|

|

SINGLE PRODUCT DOSAGE IN LOADING FUNCTIONING

|

|

| |

|

|

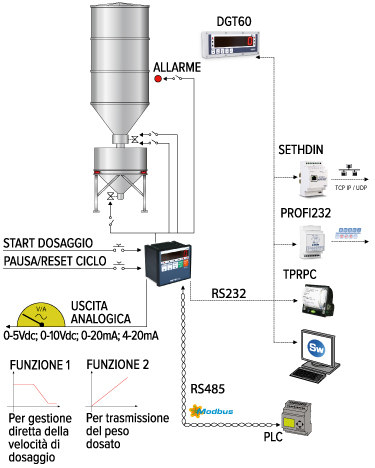

Single product loading dosage

Example of dosage system usign the DGTQF for loading routine

|

|

|

|

Configuration which allows to manage a dosage system in loading of a single product, useful for filling hoppers, silos or big bags, or guiding the operator in the manual dosages. |  |  | FUNCTIONING OF THE GUIDED MANUAL DOSAGE |

|  | - NOTE: it is advisable to use a three-light control box (available upon price estimate) in order to ease the dosage operations, in which the yellow light indicates insufficient weight, the green light indicates the target weight, and the red light indicates too much weight.

- 1. Once the dosage start command has been received, the following takes place:

- the presence of the tare and weight stability is verified,

- the execution of the automatic tare and the yellow light turns on (*), in other words, the request of material is made. - 2. When the weight is again within the lower tolerance level, both the yellow and green lights turn on (*).

- 3. When the weight is equal to the configured target, the yellow light turns off and the green light remains on.

- 4. If the weight is within the upper tolerance level, both the green and red lights turn on (*).

- 5. If the weight is over the upper tolerance level, only the red light remains turned on.

- 6. When the weight is again within the set tolerance levels, the operator gives a start impulse in order to continue with the complete unloading of the scale.

|

|

|

Available indicators en single product dosage in loading version

| | Code | Description |

| DGTQF | Microcontroller for dosage, with 2 IN and 6 OUT. 5-key keypad and LED display. |

| DGTQFAN | Microcontroller for dosage, with 2 IN, 6 OUT, analogue output. 5-key keypad and LED display. |

| DGTPF | Microcontroller for dosage with 4 IN and 6 OUT. 5-key keypad and LED display. |

| DGTPFAN | Microcontroller for dosage with 4 IN, 6 OUT and analogue output. 5-key keypad and LED display. |

| DGTPKFV2 | Indicator for dosage, with 4 IN and 6 OUT. Stainless steel case for table or panel mounting, 20-key keypad and LED display. |

| DGTPKFANV2 | Indicator for dosage, with 4 IN, 6 OUT, analog output. Stainless steel case for table or panel mounting, 20-key keypad, LED display, and standard weighing program. |

| DFWATEX2GDF | ATEX 2GD indicator for single and multi product dosage. IP68 stainless stell case, 17-key keypad and LCD display. Protection mode: ATEX II 2(2)G Ex ib [ib Gb] IIC T4 Gb for gases and ATEX II 2(2)D Ex tb [ib Db] IIIC T197°C IP65 Db for dust. To be combined always with the PW200XRDxxx series' power adapter and PW200IO option. Provided with safety instructions and the ATEX EU declaration of conformity (EN, DE, FR, ES and IT). |