|

|

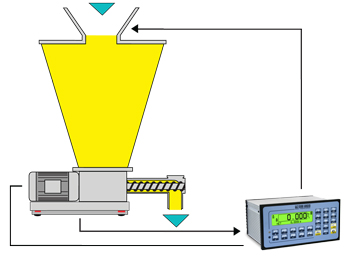

Continuous loss-in-weight dosage with flow adjustment

E-LW: dosage and adjustment of the flow of material exiting from silos, tanks, hoppers.

E-LW application example

|

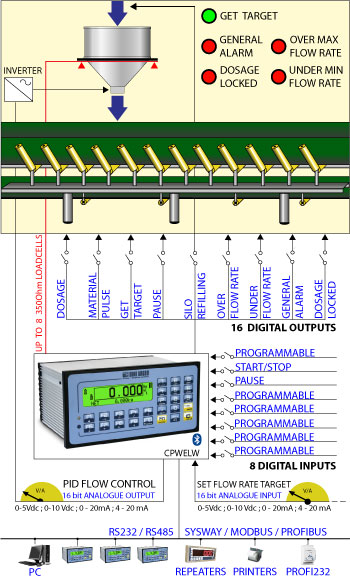

|  |  | SYSWAY, MODBUS, PROFIBUS FUNCTIONS |

|  | - READING OF THE DATA: net weight, instantaneous capacity, instantanous pid value, partial total, general total, status of the optoisolated inputs, status of the optoisolated outputs, flow target (for the controller modes), minimum flow, maximum flow, dosage time, target to be dosed, set point enabling/disabling value, scale status.

- AVAILABLE COMMANDS: dosage Start/Stop/Reset, programming of flow target, target to be dosed, dosage time, print format, reset of the totals accumulated, programming of setpoint.

|

|

|

Software version for the measurement/integration of the weight, the flow of material exiting from silos, tanks, or hoppers, with memorisation of the quantity of dosed material; possibility of adjusting the flow through the 16 bit analogue output and the PID control. Possibility of remote management of the instrument through Sysway or Modbus RTU protocols, as well as Profibus through external optional interface. |  |  | DOSAGE FUNCTIONS |

|  | - 2 selectable operation modes:

- Instantaneous reading of the flow, in g/h, kg/h or t/h with displaying of the status of the system and of the dosed total.

- Adjuster of the dosage hourly flow, with adjustment of the belt speed or of the material flow through the analogue output with completely adjustable PID adjustment algorithm (proportional, integral, derivative). - Visualisation of the hourly flow graph and wide range of data displayed on the display.

- Calibration of the flow reading function, for perfecting the dosage performances.

- Reading filter of the hourly flow with configurable incidence and speed depending on the system.

- Programmable dosage target upon weight or upon time, with relative contact.

- Programmable delay at the start, for synchronisation of various E-LW systems in the dosage of material mixtures.

- Management of the slow flow with programmable activation threshold, for more precise dosages.

- Management of the dosage total under way and general total of dosages, printable and clearable independently from each other.

- Management of the automatic dosage from remote master or through serial protocol.

- Printing of the dosage data and the total.

- Completely programmable printouts, for compatibility with any ASCII printer manageable through the serial port.

|

|

|